The beverage and food processing sectors range widely from dairy products to baked goods. With an extensive range of diversity in media processing, it is necessary to understand the unique complexities of media you will need to process.

Understand what specific valve will be required and for this, there will be a need to consider variables like –

- The pressure

- The media temperature

- The viscosity

- The exposure of the valve to the elements

Beverage and food processing valves

Direct contact valves

The material used to design direct contact valves is stainless steel as it is corrosion-resistant. It comes in direct contact with food like soda, milk, meat, juice, etc. Harsh corrosive cleaning products are used to clean but stainless-steel material can handle the corrosive agents with ease.

Utility service valves

There is no direct contact with the food but utility service sanitary valves are suitable to handle non-food related resources like steam and water needed for packaging, preparation, and foodstuff transportation.

Solenoid valves

Solenoid valves are used commonly in the food processing sector. The majority of these are designed to handle the corrosive and humid environment and severe room temperature. The material used to construct these valves is stainless steel, which has contaminant resistant characteristics. This is the key reason that solenoid valves are ideal for food processing.

You will find them employed in the abattoir and meat sector, salting systems, fish canneries, fruit & vegetable canneries as well as ready-meal sector. High pressurized solenoid valves are needed in fish fillet preparation systems, salmon packing lines, and pasteurization system.

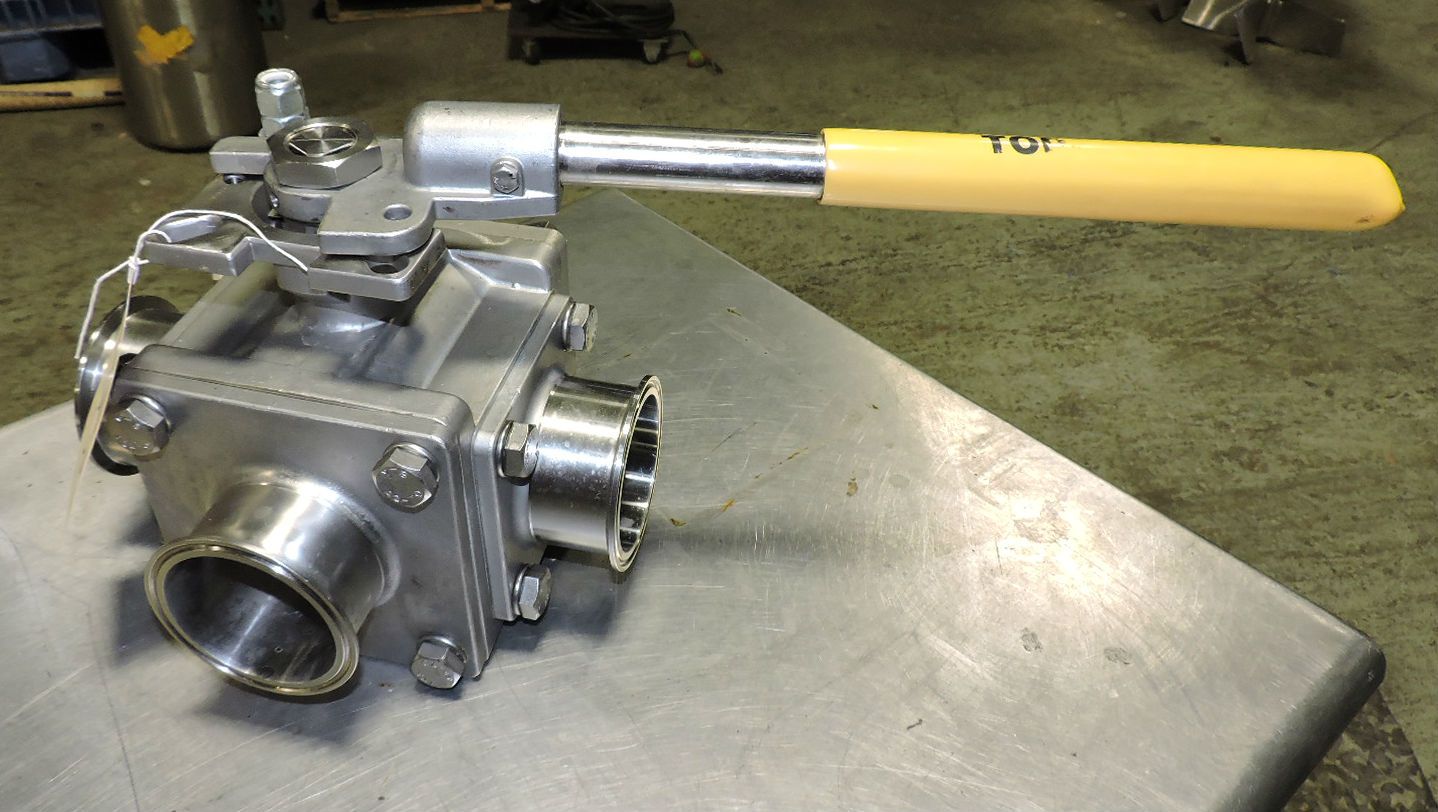

Ball valves

Applications that need sterile or clean processing makes use of sanitary ball valves. There must be no cracks or cavities to be termed as sanitary. It is essential to keep away bacteria from thriving. Sanitary ball valves shut-off tightly. Many types of valves are available including pinch, butterfly, globe, diaphragm, or knife are the names of a few. Stainless steel sanitary ball valves are a great alternative for beverage processing.

Pneumatic valves

The material used to design the pneumatic valves must not react chemically with the media or it can impact the color, taste and other characteristics. According to national standards, stainless steel material is the best. It avoids the secondary pollution of food and water source.

Different valves adjust to different media temperature and pressure. So, consider the characteristics of your preferred circulation media, while choosing a sanitary valve.

Comments